Articles

Products

A continuous separation machine that separates plant materials such as wood chips into fibers at a certain temperature and pressure. The slurry prepared by this equipment has good fiber morphology and low power consumption, so it is widely used in the fiberboard industry. It is the main fiber separation equipment. In the 1970s and 1980s, the refiner mill pulping process (TMP method) was also widely used in the paper industry.

The hot refiner mill was invented by Arne Asplund of Swedes in 1931. Since its application in industrial production in 1934, its structure and performance have been continuously improved. The diameter of large hot refining discs in developed countries can reach 1625 millimeters, the motor power can reach 9000 kilowatts, and the daily and night production can reach 400-800 tons (dry slurry).

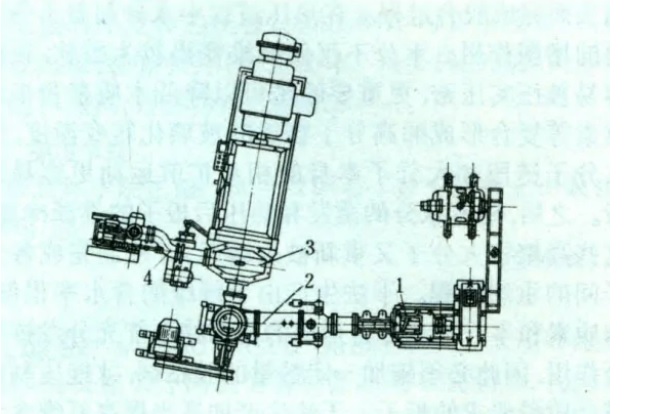

The first hot refiner mill in China was successfully designed and manufactured by Engineered wood machinery factory in the early 1960s. At present, China has been able to manufacture various thermal mills, forming a series that can meet the supporting needs of the domestic wet fiberboard industry. The diameter of the grinding disc of the QM6B refiner mill produced in China is 600mm, and the daily and night production capacity reaches 16-20 tons (dry slurry). The main body of the refiner mill is mainly composed of a feeding device, a preheating and cooking device, a grinding device, and a discharge device (see figure).

Feed device:

There are types such as piston type, screw type, and rotary valve type. The characteristic of the feeding mechanism is to continuously feed a certain amount of fiber raw materials into the preheating and cooking device, and to have good sealing performance to prevent high-pressure steam and backspraying of raw materials. The piston type feeding mechanism used in the early stage has been replaced by a screw type feeding mechanism. The feeder is a conical spiral with variable pitch, which compresses fiber raw materials to form a material plug, achieving the goal of preventing backflow. The compression ratio is usually used to indicate the degree of compaction of the material within the spiral. The actual volume ratio of one screw groove at the beginning and one screw groove at the end of the feeding spiral is called the compression ratio, which is generally about 1.6-2.2. When using wood chips as raw materials, the smaller value is taken, and when using grass as raw materials, the larger value is taken. At present, some new types of hot refiner mills use rotary feed valves, which can reduce the squeezing and cutting damage to fibers during the operation of the feeder. The power consumption is also lower than that of the spiral type, and there is no backflow phenomenon. However, high manufacturing accuracy is required and steam consumption is also high.

Preheating cooking device:

Its function is to soften the raw material, making it easier for fiber separation. The main part is the preheating tank, which is divided into two parts: horizontal preheating tank and vertical preheating tank. In recent years, there has been a trend towards using elevated vertical digesters, which can easily control the cooking time of materials by monitoring the height of the materials inside the tank. The commonly used level controllers are resistive level indicators and γ Radiographic material level indicator.

Grinding device:

It is the main body of the hot refiner mill, including the spindle, grinding chamber, grinding disc, grinding disc pressure device, and fine adjustment device. The grinding disc includes a fixed disc and a movable disc, and the grinding disc is fixed to the grinding disc with screws. The grinding disc is a working part that directly plays a grinding role. To adapt to different raw materials and meet the requirements of improving slurry quality, there are various types and tooth shapes of grinding discs. The grinding material is commonly made of composite cast iron, with a white iron tooth surface and a hardness of approximately HB430-477. There are also grinding discs made of special stainless steel casting, which greatly improve their service life. The grinding disc pressurization device adopts hydraulic pressure, which ensures that the grinding disc generates a certain grinding pressure on the raw materials during the operation of the hot refiner mill. When hard objects such as metal blocks are mixed between the grinding discs at the same time, the grinding disc can be quickly separated. During maintenance and replacement of the grinding discs, the switching valve can be operated to move the moving disc back a certain distance. The fine-tuning device for grinding disc clearance is often connected to a pressure device, which uses a handwheel to produce a small amount of axial movement of the spindle through structures such as worm gears, screw nuts, etc., accurately adjusting the grinding disc clearance.

Discharge device:

There are periodic discharge devices and continuous discharge devices. The most common periodic discharge device is a two-stage reciprocating elbow discharge device, also known as an S-shaped discharge valve. Adjusting the working stroke and frequency of the discharge valve can regulate the discharge of steam and fibers, and maintain the normal working pressure in the grinding chamber. The new type of hot refiner mill adopts a continuous discharge device, greatly simplifying the structure of the discharge device. It utilizes steam pressure for continuous discharge, eliminates the discharge transmission mechanism, does not require power, reduces noise, and simplifies operation. As long as designed and adjusted properly, steam consumption does not increase.

The development trend of thermal mills is: ① towards large, high-speed, and high-power directions; ② Reduce the working pressure of the hot refiner mill and achieve low-temperature pulping to reduce wood leaching; ③ Developing a combination type grinding disc, where high-pressure water for dilution and cooling is introduced between the inner and outer grinding areas to complete precision grinding and hot grinding in the same equipment, is called the one-time slurry method; ④ Effective monitoring and control of material level, cooking time, gap between grinding discs, and wear of grinding discs are achieved using various new technologies such as mechanical, electrical, instrumentation, and optical.